Unique RRR filter elements

Triple R’s continuous investment in research and development delivers the highest standard of efficiency in oil filtration. Protecting your investments while boosting productivity.

Our RRR filter elements are designed to cleanse industrial oils, removing everything from solid particles to water to sludge, varnish and oxidation residues. 3 in 1, all within a single element – a Triple R unique, unmatched by any filter manufacturer worldwide.

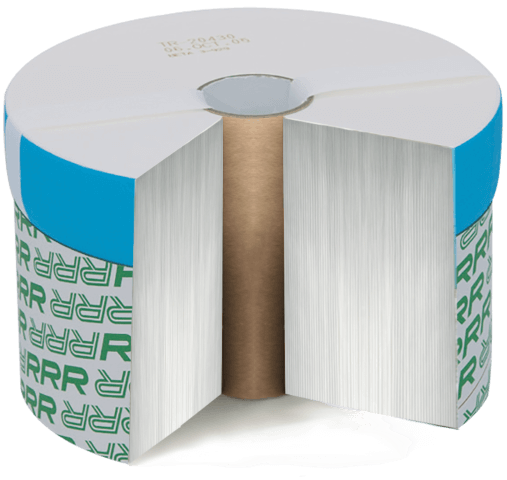

How RRR filter cartridges work

st stage

Big particles are retained on the top of the filter cartridge

nd stage

Small particles are trapped in the mid stage of the filter element

rd stage

The smallest particles are trapped in the lower and compressed part of the filter cartridge

A revolutionary 3-in-1 element design allows to guarantee absolute filtration effectiveness.

The filter design forces the oil to flow through 114mm of engineered filter media and creates 3 distinct stages of filtration. The lower part is compressed by a carton box, creating an even finer filter medium.

- Big particles stay on top of the element

- Smaller particles are captured in the upper non-compressed part

- The smallest particles are captured in the lower compressed part

The filter becomes an excellent diagnostic tool as big PARTICLES are retained on top.

The cellulose filter media absorbs WATER drops and therefore dries the oil to less than 100 ppm.

The industry’s thickest filter, 114mm to flow trough, combined with Triple R’s filter media, results in the unique ability to absorb and remove oil oxidation residues, well known as VARNISH, or sludge deposits.

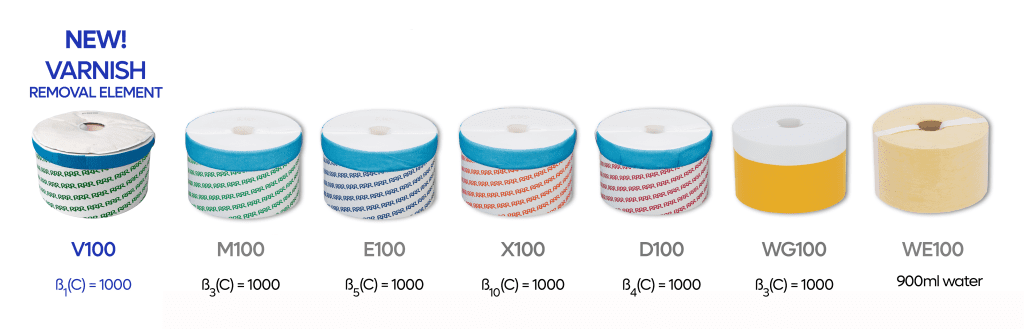

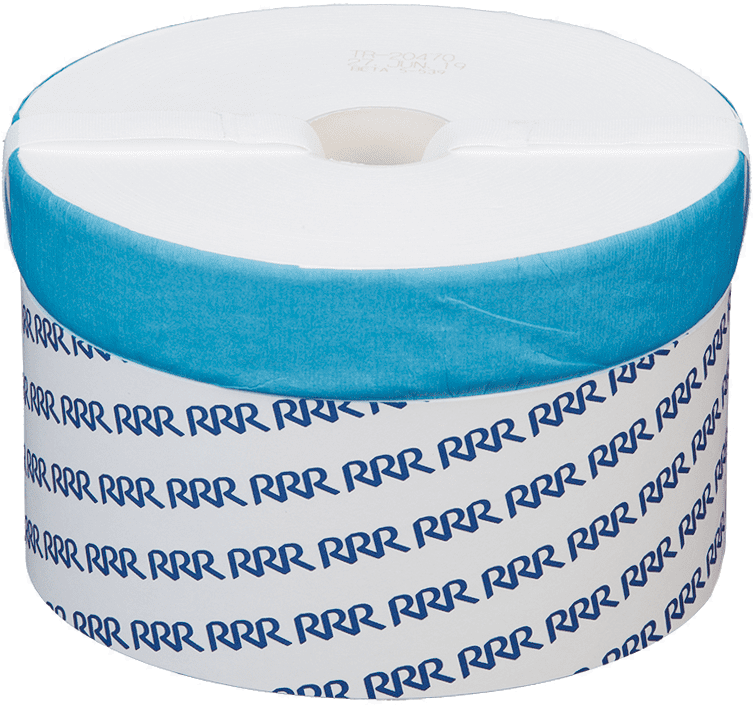

A unique range of filter elements engineered to fit every application.

Triple R filter elements are all Multipass-tested and guarantee consistent and reproducible micron ratings and filtration efficiency. Contrary to others, all our micron values, dirt, and water absorption capacities are officially documented.

The filter element range comes in 4 sizes (30, 50, 100, and 300), in various filter materials from cellulose to polyester to PP, and in 2 different setups (standard or ‘double stage’ D-series setups).

After 4 years of engineering and research, we are pleased to introduce a world-first: a new V100 VARNISH REMOVAL filter element with a 1-micron absolute filtration efficiency!

V-SERIES = 1 micron absolute

- ß-ratio’s: ß1 >400 and ß3 = 1000

- For turbine oil and hydraulic oil – 3 cSt up to 180 cSt

- Sizes: with M100, E100 and X100

- various logo print

M-SERIES = 3 micron absolute

- ß-ratio’s: ß2 >400 and ß3 = 1000

- For hydraulic oil and Diesel; for 3 cSt up to 180 cSt

- Sizes: M30, M50, M100, M300

- Green logo print

E-SERIES = 5 micron absolute

- ß-ratio: ß3 >75 and ß5=1000

- For engine oil – 46cSt up to 180cSt

- Sizes: E30, E50, E100, E300

- Blue logo print

X-SERIES = 10 micron absolute

- ß-ratio’s: ß5 >75 and ß10=1000

- For high viscosity oil, and engine oil for a longer filter element life.

- Sizes: X30, X50, X100, X300

- Orange logo print

D-SERIES = 4 micron absolute

- ß-ratio’s: ß3 >75 and ß4=1000

- +80% higher dirt holding capacity

- Sizes: M100, M300

- Red logo print

WG-SERIES = yellow print

- WG-series, 5 micron : ß5 >75, for water glycol fluids

- Models: WG100 (10µ) – DWG100 (5µ)

- Yellow support band

WE100 = no print

- WE100, a unique filter that acts like a sponge, absorbs up to 900 ml of water, down to <80 ppm.

How to change a TRIPLE R filter insert

Triple R filter cartridges are easy to replace with a little precaution, without even spilling a drop of oil. And you don’t need any special tools to open the filter. Really practical for replacing your filter quickly and cleanly.

Each RRR filter element is vacuum packed. First remove the outer protective plastic film (except for the WE100 filter!).

In addition, there is always a plastic bag in the center tube, especially for collecting the dirty filter. Slide the bag over the filter and carefully pull the contaminated filter element by the straps into the plastic bag.

Expert tip

Use Triple R to analyze the condition of your system and your oil.

When opening the lid of a Triple R filter housing or when changing a filter element, you can quickly check the top of the filter element and see the color of the oil and the solid particles retained on top of the filter element.

The appearance of the filter element and the type of contaminants present on the top allow you to conclude your system’s condition quickly.

Filter cartridges in flexible sizing

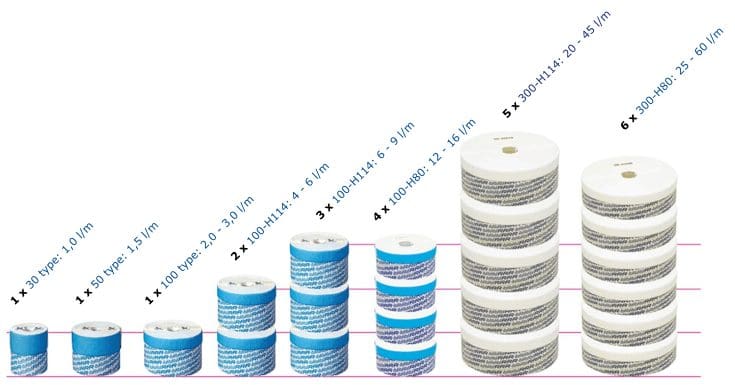

Triple R filter systems can be used for engines with just 30-litre oil content, up to large machinery and oil volumes, and up to 100.000 liters. Ask your Triple R representative for detailed information.

Therefore, Triple R offers a wide range of filter housings that use from 1 up to 6 RRR filter elements.

That allows increasing the flow rate or adapting the filter system to various viscosity ranges, from 2-3 cSt up to 320 cSt., and allows the use of Triple R bypass filters for cleaning large oil volumes and for achieving significant flow rates exceeding 100 l/min (>6,000 l/hour).

Contact us for your RRR Filter Inserts

or other filtration related questions

Experience our top-notch filtration and oil cleaning solutions designed to meet your specific needs.

Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations.

"*" indicates required fields